Blog

1. Basics: What Are Cloth‑Backed and Paper‑Backed Sandpaper?

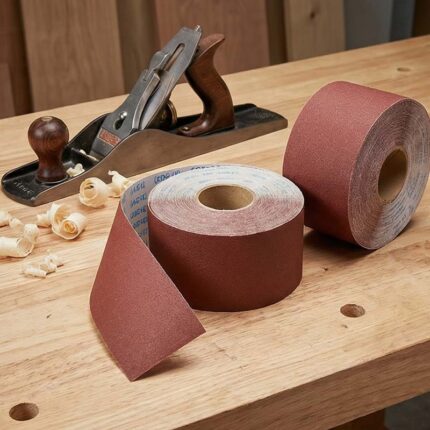

Cloth‑backed sandpaper

- Uses fabric (cotton or synthetic cloth) as the backing instead of paper.

- Very flexible and tear‑resistant, lasts longer than regular paper sandpaper.

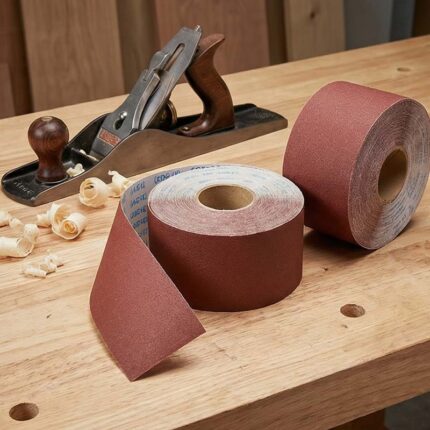

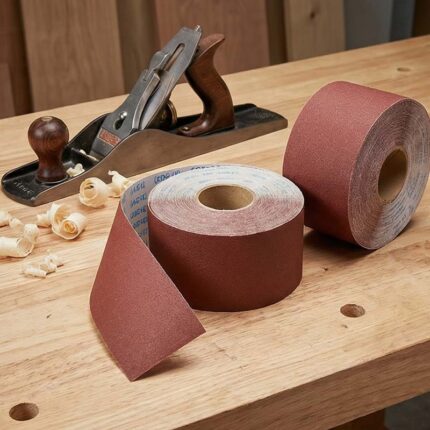

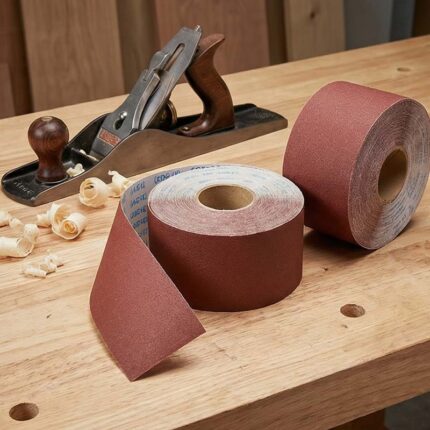

- Often sold as shop rolls (e.g. 100mm x 5m rolls you tear by hand).

Paper‑backed sandpaper

- Uses different weights of paper as the backing.

- Common formats: sheets, discs, belts for random orbital sanders etc.

- Cheaper and good for large, flat surfaces, but tears and creases more easily.

2. Quick Comparison: Cloth vs. Paper

| Feature | Cloth‑Backed Sandpaper | Paper‑Backed Sandpaper |

| Durability | High – Tear‑resistant, long‑lasting backing. Ideal for heavy use. | Mittel – Easier to tear, especially at edges or when folded. |

| Flexibility | Excellent – Wraps easily around curves, spindles, and complex shapes without cracking. | Limited – Stiffer backing. Tends to crack or crease when folded tightly. |

| Best For | Metalworking, wood turning, contour sanding, and sharp edges. | Flat surfaces (tabletops, panels), light sanding, and random orbital sanders. |

| Wet Sanding | Very Good – Many cloth backings are water‑resistant and durable when wet. | Requires Specific Type – Only works if it is specifically “Wet/Dry” paper. |

| Format | Often sold as Shop Rolls (tear to length) or belts. | Typically sold as Sheets, Discs, or Belts. |

| Cost | Higher upfront cost per roll, but often cheaper per job due to longer life. | Lower upfront cost per pack, but may use more sheets for the same task. |

| Tear by Hand | Yes – Shop rolls are designed to be torn cleanly by hand to any length. | Sometimes – Often requires scissors or a knife to cut cleanly. |

In one line:

- Use cloth‑backed sandpaper when you need durability, flexibility and contour sanding.

- Use paper‑backed sandpaper for occasional, flat‑surface sanding.

3. When Should You Use Cloth Sandpaper?

3.1 Woodworking: Curves, Turning and Edges

Cloth‑backed sandpaper is ideal in woodworking when you:

- Sand turned pieces (spindles, bowls, handles) on a lathe;

- Work on profiles, mouldings and trim with curves;

- Knock down sharp edges where paper tears quickly;

- Need to tear narrow strips to wrap around parts.

Typical grits:

- P80–P120: shaping and removing machine marks

- P150–P240: general smoothing before finish

- P320–P600: fine sanding and between‑coat sanding

3.2 Metalworking: Deburring, Rust Removal and Prep

Metal is tough on abrasives. Cloth‑backed sandpaper is usually the better choice for:

- Deburring cut edges and holes;

- Removing rust and scale;

- Preparing steel or aluminum before paint or coating;

- Blending welds and smoothing small parts.

Suggested grits:

- P40–P120: heavy stock removal, deburring

- P180–P320: surface prep before coating

- P400–P800: pre‑polishing and smoothing

3.3 Auto Body and Equipment Repair

In auto body work and equipment repair, you often deal with:

- Curved panels and complex shapes;

- Tight areas around seams, trims and brackets;

- Mixed surfaces: metal, filler and primers.

Cloth shop rolls let you:

- Tear thin strips for detail areas;

- Use the same abrasive dry and wet;

- Keep key grits on the bench and pull what you need.

4. When Is Paper Sandpaper the Better Choice?

4.1 Large, Flat Surface Sanding

For:

- Tabletops, doors, cabinets and large panels;

- Sanding with random orbital or palm sanders;

Paper discs or sheets are usually more economical. The backing is fully supported by the sanding pad, so cloth strength is less critical.

4.2 Light‑Duty or Occasional Use

English:

If you:

- Only sand occasionally;

- Have a small, one‑off project;

Standard paper sandpaper is fine and keeps the upfront cost low.

4.3 Between‑Coat Sanding on Flat Finishes

For between‑coat sanding on paint, primer or clear coats:

- You’re in higher grits (P320–P800);

- Pressure is light and surfaces are usually flat.

Here, paper wet/dry sheets with a sanding block can perform very well.

5. Simple Decision Guide: Cloth or Paper?

- Mostly metal, curves, edges, workshop use → choose cloth‑backed sandpaper / cloth shop rolls.

- Mostly flat panels and occasional projects → choose paper‑backed sandpaper.

- Using power sanders for large areas → paper discs/sheets on machines.

- Doing detailed hand work and small parts → cloth shop rolls you can tear to length.

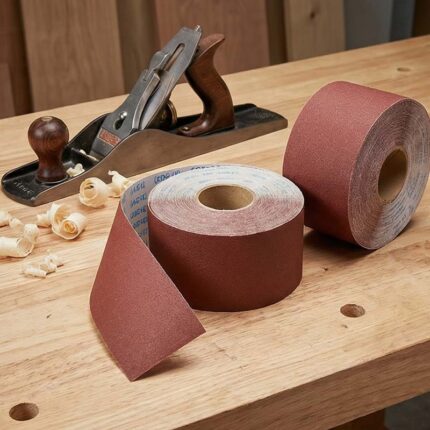

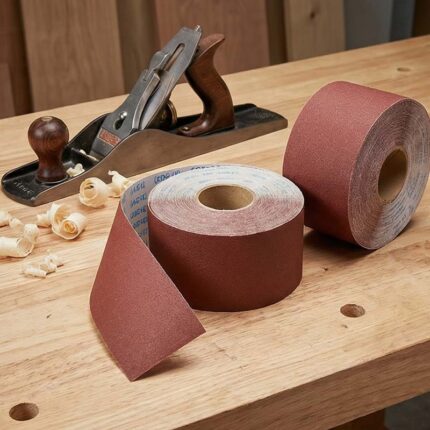

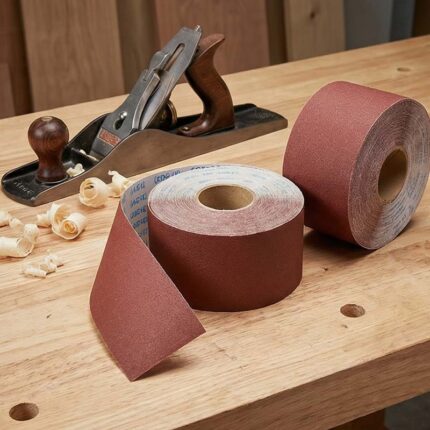

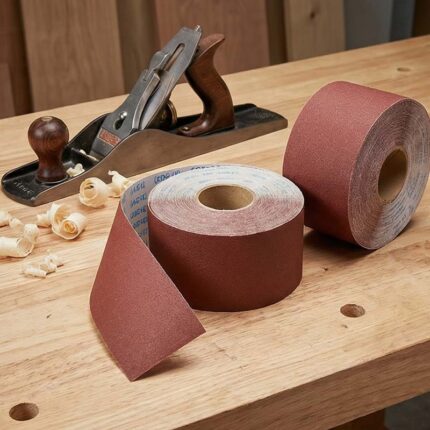

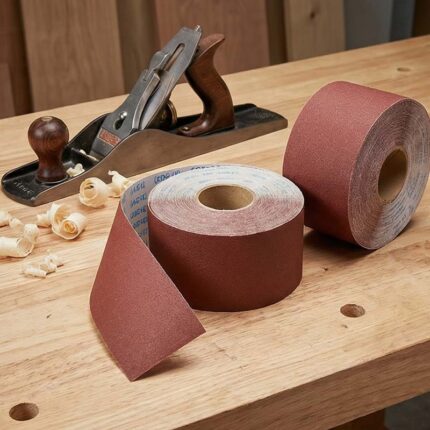

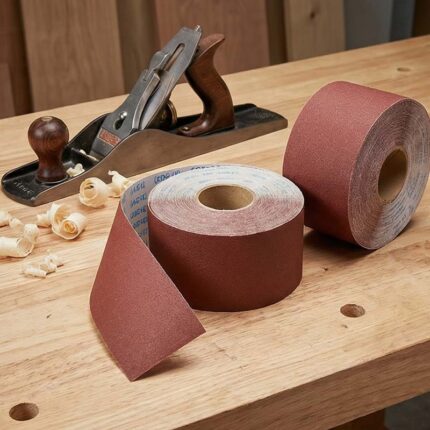

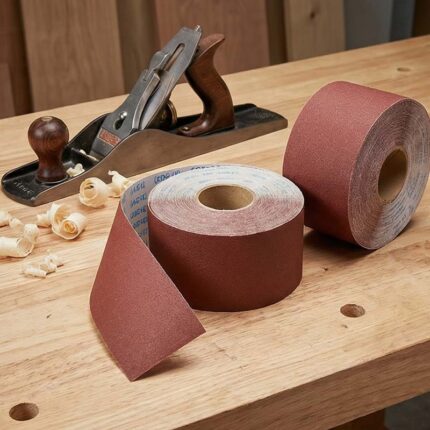

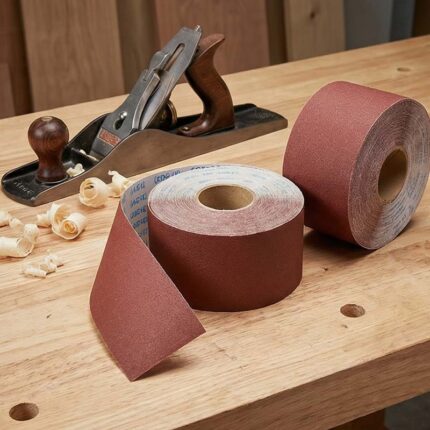

P120 Schleifpapierrolle 100mm × 5m

- Schleifpapierrolle mit 120er-Körnung, ideal zum Schleifen von Holz- und Metalloberflächen.

- Leicht zu zerreißen und auf jede beliebige Größe zu schneiden.

- Strapazierfähig und langlebig mit flexibler Stoffunterlage.

- Sowohl für den trockenen als auch für den nassen Einsatz geeignet.

- Vielseitig einsetzbar für eine Vielzahl von Schleifanwendungen.

- Nach Gebrauch leicht zu reinigen.

- Online verfügbar mit kostenlosem Versand.

999 vorrätig

Verwandte Beiträge

Cloth vs. Paper Sandpaper: Which Should You Use and When?

Was ist Schleifpapierkörnung? (Vollständiger Leitfaden 2026)

Kategorie-Leitfaden

Neueste Updates

- Cloth vs. Paper Sandpaper: Which Should You Use and When? Januar 16, 2026

- Was ist Schleifpapierkörnung? (Vollständiger Leitfaden 2026) Januar 8, 2026

Unsere Auswahl für Sie

-

P800 Tuch Sandpapier Shop Rolle - 100mm (4 Zoll) x 5m

P800 Tuch Sandpapier Shop Rolle - 100mm (4 Zoll) x 5m

$25.9原价为:$25.9。$19.9当前价格为:$19.9。 -

P600 Schleifpapier Rolle 100mm × 5m

P600 Schleifpapier Rolle 100mm × 5m

$25.9原价为:$25.9。$19.9当前价格为:$19.9。 -

P400 Schleifpapier Rolle 100mm x 5m

P400 Schleifpapier Rolle 100mm x 5m

$23.9原价为:$23.9。$18.9当前价格为:$18.9。 -

P320 Schleifpapier Rolle 100mm × 5m

P320 Schleifpapier Rolle 100mm × 5m

$19.9原价为:$19.9。$15.9当前价格为:$15.9。 -

P240 Schleifpapier Rolle 100mm × 5m

P240 Schleifpapier Rolle 100mm × 5m

$19.9原价为:$19.9。$15.9当前价格为:$15.9。

Produkt-Etiketten

Neueste Produktbewertungen

-

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Jacques

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Jacques -

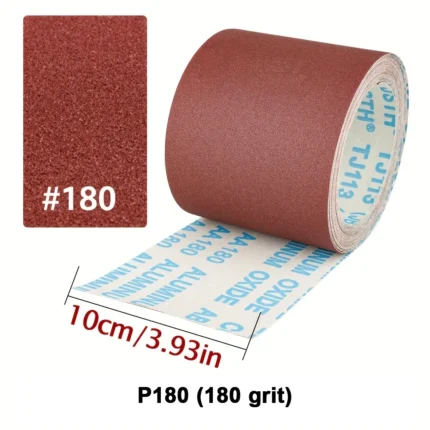

P180 Schleifpapier Rolle 100mm × 5m

评分 5 / 5von Jacques

P180 Schleifpapier Rolle 100mm × 5m

评分 5 / 5von Jacques -

P150 Schleifpapier Rolle 100mm × 5m

评分 5 / 5von Keith Parker

P150 Schleifpapier Rolle 100mm × 5m

评分 5 / 5von Keith Parker -

P40 100mm Schleifpapier Rolle - 5m

评分 5 / 5von lalaxiari666

P40 100mm Schleifpapier Rolle - 5m

评分 5 / 5von lalaxiari666 -

P60 100mm Schleifpapier Rolle - 5m

评分 5 / 5von Keith Parker

P60 100mm Schleifpapier Rolle - 5m

评分 5 / 5von Keith Parker -

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 4 / 5von Gio

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 4 / 5von Gio -

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Liz

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Liz -

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Luca

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Luca -

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Colin Murray

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von Colin Murray -

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von John Penny

P40-P1000 Schleifpapier-Rollensatz 100mm (ca. 4inch), 5 Rollen

评分 5 / 5von John Penny